The in-line zinc anode is attached to the bonding wire, thereby protecting all metal parts(heaters,lights,rails,etc.) from galvanic corrosion. Zinc anodes will sacrifice themselves and corrode before all other metals in the pool. Zinc anodes need to be replaced approximately every 4-5 years.

Any time you have different metals (copper, stainless steel, etc.) in a salt water pool, you create a battery. Some amount of current flows between the metals. The electrons that make up the current are supplied by one of the metals, giving up bits of itself in the form of metal ions to the pool water. This is called galvanic corrosion. Galvanic corrosion causes plaster discoloration and metal erosion. The best way to inhibit the effect of galvanic corrosion is to use a zinc anode. Zinc is a metal that gives up its metal ions faster than other metals in the pool. In other words, the zinc anode will erode instead of other metals (pool light, rails, heater, light niche, ladder, etc.). The zinc ions will not discolor the pool plaster. The zinc anode should be replaced after half of it has eroded. This takes approximately 3 years.

![]()

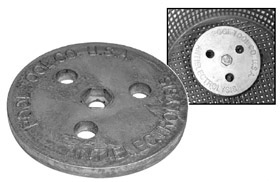

The inline zinc anode is attached to the bonding wire thereby protecting all metal parts against the effects of galvanic corrosion. Available in 1-1/2” and 2”. The see through housing allows the anode to be easily replaced when depleted. No replumbing required. A must for salt water pools. Replacement Anode Kit (No. 104 C-R)

The #104-PS can be installed on 2in PVC Flex or 2in PVC Rigid pipe.

PARTS INCLUDED:

1. Flex PVC Support Fitting

2. Bracket

3. Anode Chamber

Zinc Anode Weight was designed to stop metal erosion, and plaster discoloration due to galvanic corrosion. Keeps skimmer basket in place. Bolts permanently inside or outside any skimmer basket..

Helps protect heaters, pool lights and rails from damage due to galvanic corrosion. Inline zinc anode for new installations - 4 feet of #8 copper bonding wire included.

The #104-PS SPIGOT allows the anode chamber to be glued into a 1” tee. Note: A 1 1/2” or 2” tee can be reduced to accept the 1” spigot.

Anti Electrolysis Zinc Anode helps protect pool lights from damage due to galvanic corrosion. • Black stain around pool light. • Erosion of the stainless steel light & nitch. • Discoloration of the chrome face plate.

Slips into any 2” Tee! The inline zinc anode is attached to the bonding wire thereby protecting all metal parts against the effects of galvanic corrosion. The see through housing allows the anode to be easily replaced when depleted.

Elimates plaster staining and metal corrosion due to galvanic corrosion. Permanently bolts to ladder or grab rail below water line. A must for salt water pools.

The Zinc Anode will sacrifice itself and corrode before all other metals in the pool. In doing so, the anode protects other metal parts from galvanic corrosion. The Zinc Anode will need to be replaced approximately every 3 years or when it is 1/2 its original size. * Replacement Kit Includes Zinc Anode * Thru Rod * New Cap * "O" Ring